If the structures are shifted from its original

position to new site, the process is known as moving buildings.

Moving buildings is based on the following

factors:

• Motivations to move buildings

• Groundwork of structure

• Moving building method

• Types of moving buildings

• Safety measures required for moving of the structure successfully

Motivations

to Move Buildings: Due to several reasons, it becomes necessary to shift

buildings from its original positions to new locations. As for instance –

resist demolishing of historical structures and retain them when their

locations are essential for industrial purposes or as a result of increasing in

population density, new residential buildings should be developed.

Another

reason is that building is not built up as per exact plans and arrangements.

Therefore, buildings should have been shifted to make necessary arrangements.

The

process for moving building to the new position will be cost-effective as

compared to demolish it and then develop new buildings.

In some cases, the residential areas are greatly affected by

recurring catastrophic natural events like flooding, so, under this

circumstance moving buildings will be the only alternative.

Historical

houses are frequently moved and collected to build up a historical village.

Underpinning of Structure: Building underpinning plays an

important role in the process of moving buildings and several methods are

available through which underpinning of structure is carried out.

The

Underpinning methods applied for moving buildings range from underpinning by

continuous strip foundation, underpinning with piers or bases, underpinning by

piles, pretest methods of underpinning, underpinning by injections, and

freezing and thawing underpinning.

Moving Building Process: Generally, underpinning is the most

effective method in the process of moving building. But sound knowledge and

experience are required to execute such vital operation.

Usually,

moving building is accomplished on the basis of sufficient surveying of the

structure and calculation of loads properly as well as in-depth investigation

and analysis of soils at new site of the building and at tracks on which the

building is shifted, and exact jacking along with equalizing measuring strain

equipment.

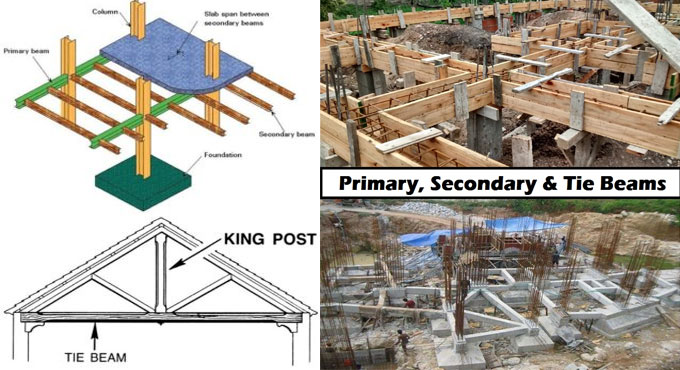

Moving

building method comprises of the provision of a system of beams on which the

building weight is retained, and these beams are arranged on a roller or wheel

carriage that is set on rail track. The rail track is arranged on the ground as

per the preferred direction.

~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.constructioncost.co

~~~~~~~~~~~~~~~~~~~~~~