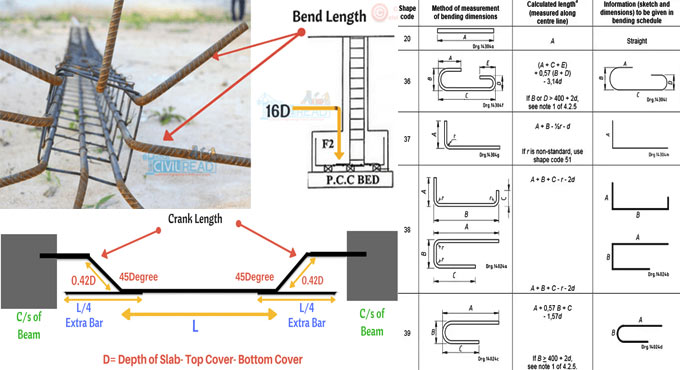

RC Slab: RC Slab stands for a horizontal structural component of steel reinforced concrete. Generally, the thickness of RC slab varies from 100mm to 500mm. RC Slabs are frequently applied as floorings, ceilings etc. Slabs are supported on two sides only or contain beams on all four sides.

RC slabs are erected with formwork, that is generally created with wooden planks, boards, plastic & steel. In recent times, prefabricated RC slabs are also utilized. RC Slab is also termed as Reinforced Concrete Slab that arranges reinforcement for retaining the strength of the structure. Straight bar and alternative cranked bars are also applied as reinforcement in the RC slabs.

RB slabs: RB slab stands for a reinforced brick slab that is suitable for floorings and ceilings. RB slab is erected with steel reinforcement arranging spacing with the bricks. The construction cost of RB slab is less with regard to RC slab.

An RC slab alias Reinforced Cement slab is found in buildings and in bridge construction. The reinforcement is provided with steel bars which are arranged with some distances according to design and based on the load the slab has to undergo.

An RB slab alias Reinforced Brick slab is ideal for roofs in buildings. It is less costly as compared to RC slabs. The reinforcement is provided with steel bars which are arranged with some distances according to design and based on the load the slab has to undergo.

The distance among the bars is occupied by bricks which are arranged on its edge. The depth of the slab remains 4.5 in. The bars are provided among the bricks in both directions. The cement-sand mortar along with least possible water quantity is used to fill up the distance among the bars.