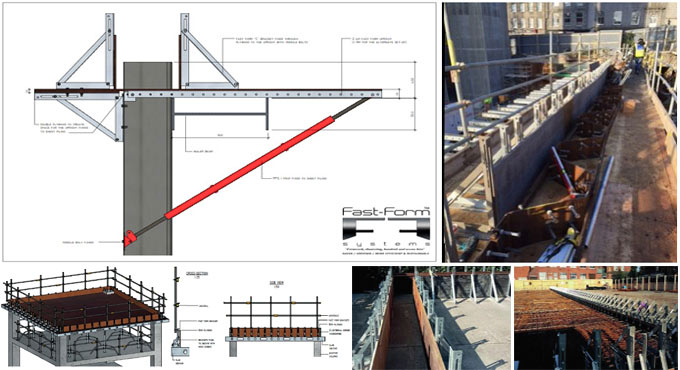

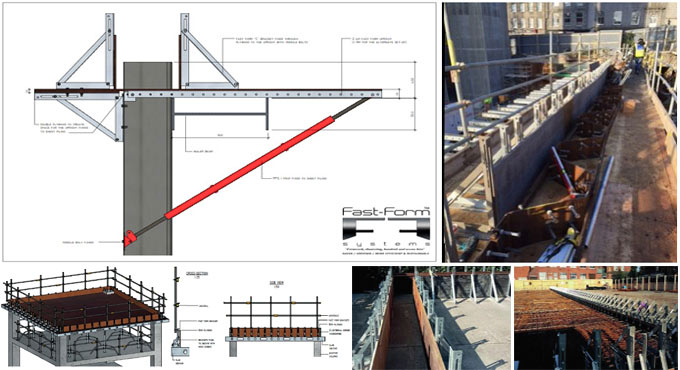

Fast-Form provides complete solution for different types of pile cap, slab, base, beam, wall and sheet pile capping beam formwork whether they come in straight or radius, single or double sided.

This system can efficiently bolts together to facilitate casting kickers, plinths, hang bolts as well as monolithic bund walls etc.

There are 2 types of bases to pin directly to hard-core and ground by means of road pins, or bolt with re-usable concrete bolts to slabs and blinding concrete or even fasten them to decking with wood screws.

This system can be used without any difficulty. Just attach the brackets in a line and plumb up, screw on your ply from behind and pour your concrete.

Brackets are angled forward or back to make adjustment with sloping and battered pours along with irregular ground, thus making them much more compliant as compared to timber or panel systems.

The brackets are generated from superior grade galvanized steel to get rid of rust and they have longevity of 25 years plus. They are strong and do not get damaged. They can be also used underwater. Different sizes are available which range from 150 / 200 / 400 / 600 / 800 / 1200 & 1800mm high.

This system can efficiently bolts together to facilitate casting kickers, plinths, hang bolts as well as monolithic bund walls etc.

There are 2 types of bases to pin directly to hard-core and ground by means of road pins, or bolt with re-usable concrete bolts to slabs and blinding concrete or even fasten them to decking with wood screws.

This system can be used without any difficulty. Just attach the brackets in a line and plumb up, screw on your ply from behind and pour your concrete.

Brackets are angled forward or back to make adjustment with sloping and battered pours along with irregular ground, thus making them much more compliant as compared to timber or panel systems.

The brackets are generated from superior grade galvanized steel to get rid of rust and they have longevity of 25 years plus. They are strong and do not get damaged. They can be also used underwater. Different sizes are available which range from 150 / 200 / 400 / 600 / 800 / 1200 & 1800mm high.

KEY BENEFITS:

• SAFETY: Access, handrails & toe boards, lightweight system that can be easily set up manually instantly and securely.

• SPEED: No need of de-nailing, lightweight and user-friendly system much faster as compared to conventional process and very simple to use with low labour skill levels.

• SPEED: No need of de-nailing, lightweight and user-friendly system much faster as compared to conventional process and very simple to use with low labour skill levels.

• COST: It is very cost-effective as compared to timber with reduced labour and plant costs.

• ENVIROMENTAL: Little or no timber wastage and 100% completely recyclable materials which significantly minimize carbon emission deliveries.

• BETTER FINISH: Fair face finishes are obtained easily. The brackets are available with an F4 finish. So, fewer remedial works are required. Ply is fixed from behind systems, so, there is no marks on face of the concrete and any grade ply can be utilized as per your requirement.

• ENVIROMENTAL: Little or no timber wastage and 100% completely recyclable materials which significantly minimize carbon emission deliveries.

• BETTER FINISH: Fair face finishes are obtained easily. The brackets are available with an F4 finish. So, fewer remedial works are required. Ply is fixed from behind systems, so, there is no marks on face of the concrete and any grade ply can be utilized as per your requirement.

To get more information, visit www.fastformsystems.com