When the materials consume water, dampness in any building happens. Dampness is harmful for the residents of the building.

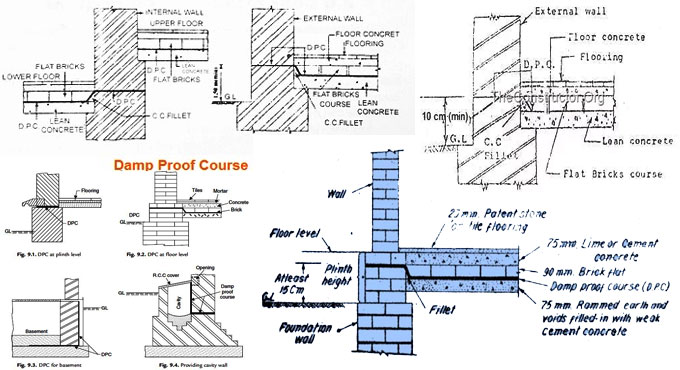

Damp Proof Course(DPC): The purpose of a course is to resist the penetration of the damp into the building and it is called as damp proof course(DPC). DPC should be provided when the construction of the building is started.

Reasons for Dampness: The dampness happens for the following reasons -

1. Ground Water Table: When the groundwater table is high, it significantly impact the foundation since the building material utilized for foundation consumes the water from the ground through capillary action.

2. Rain: When there is no proper protection for the external walls, then rainwater may harm the building.

3. When the building is situated in such an area that the water can’t be easily discharged, dampness will occur.

4. There is also possibility for dampness due to bad workmanship in construction.

5. When the walls are constructed afresh, dampness may occur for a short period.

6. If the slope of a roof remains very flat, the rainwater may enter and water is temporarily stockpiled on the roof.

7. There should be proper damp proofing course on the uncovered tops of the parapet walls and compound walls so that the damp can’t penetrate through these exposed tops.

Impacts of Dampness - The dampness may provide the following harmful effects:

1. The plaster will be soothed and may crumble. 2. Electric fitting will be affected. 3. Distempers or paints will be damaged. 4. Unhygienic conditions will be created for dwellers. 5. Growth of termites. 6. Steel utilized in building construction will be eroded.

7. Unattractive patches will develop on the wall surface and ceiling. 8. The material utilized as floor covering will be damaged. 9. Due to continuous existence of moisture in the walls, efflorescence will occur and it results in detaching of stone, bricks, tiles etc.

Methods of Damp Proofing - To get rid of dampness, the following techniques should be applied:

1. Application of Damp Proof Course: Damp proof course stands for the layer of materials like bituminous, cement, stones etc.

They are arranged in the building at all suitable positions from where water may penetrate the building. Normally, it is arranged in the building at plinth level for walls, over the concrete bed for flooring.

2. Surface Treatment: Under this method, a thin film of water repellent material is arranged over the surface which fills the holes of the materials of the building which are uncovered to the moisture.

3. Integral Damp Proofing Treatment: Under this method, water repelled compounds are blended to the concrete or mortar throughout the mixing process of concrete. These compounds function as barriers and resist the entry of moisture to the building.

4. Cavity Wall or Hollow Wall: It comprises of cavity or air drains into the wall to resist the rising of moisture from the ground to the wall.

5. Pressure Grouting or Cementation: Under this method, holes are drilled at the various sections of the building at selected points. Then thin cement paste is plunged into the holes by pressure to make the structure water-resistant.

~~~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.constructioncost.co

~~~~~~~~~~~~~~~~~~~~~~~~