For a site engineer, it is essential to work out the cutting length of bars based on the slab dimensions and provided instructions to the bar benders.

If the construction work is intended for the small area, the reinforcement detailing can be transferred to the bar benders. They will deal with the cutting length. But be careful that it may not be perfect as they do not consider the bends and cranks. They may provide some additional inches to the bars for the bends which are fully imperfect. Therefore, to get rid of this issue, a site engineer should try to compute calculate the cutting length independently.

In this article, detailed explanation is given for working out the length for reinforcement bars of slab.

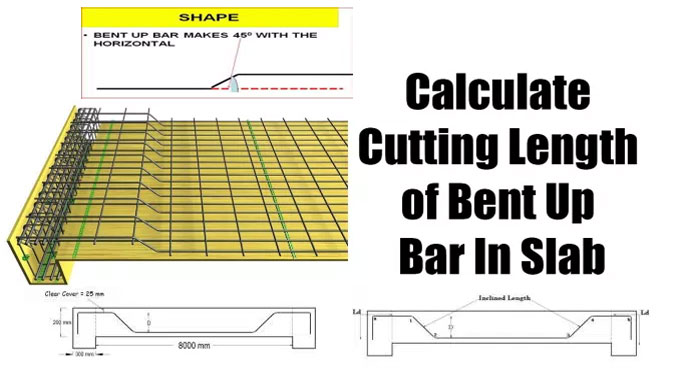

The calculation is made on the following dimensions :-

Diameter of the bar = 12 mm

Clear Cover = 25 mm

Clear Span (L) = 8000

Slab Thickness = 200 mm

Development Length(Ld) = 40d

Clear Cover = 25 mm

Clear Span (L) = 8000

Slab Thickness = 200 mm

Development Length(Ld) = 40d

Process for computation

Cutting Length = Clear Span of Slab + (2 x Development Length) + (2 x inclined length) – (45° bend x 4) – (90° bend x 2)

Inclined length = D/(sin 45°) – dD/ (tan 45°) = (D/0.7071) – (D/1)= (1D – 0.7071D)/0.7071= 0.42 D

There exist four 45°bends at the inner side (1,2,3 & 4) and two 90° bends ( a,b ).

45 ° = 1d; 90 ° = 2d

Cutting Length = Clear Span of Slab + (2 X Ld) +(2 x 0.42D) – (1d x 4) – (2d x 2) [BBS Shape Codes]

Inclined length = D/(sin 45°) – dD/ (tan 45°) = (D/0.7071) – (D/1)= (1D – 0.7071D)/0.7071= 0.42 D

There exist four 45°bends at the inner side (1,2,3 & 4) and two 90° bends ( a,b ).

45 ° = 1d; 90 ° = 2d

Cutting Length = Clear Span of Slab + (2 X Ld) +(2 x 0.42D) – (1d x 4) – (2d x 2) [BBS Shape Codes]

~~~~~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.constructioncost.co

~~~~~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.constructioncost.co

~~~~~~~~~~~~~~~~~~~~~~~~~~